The Electric Vehicle Transition Relies on Structurally Sound Solutions

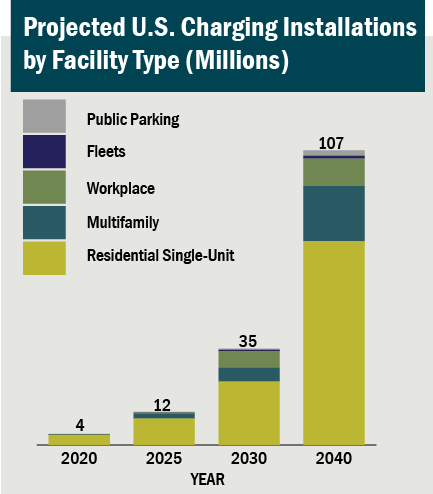

Structural engineers play a critical role in the transition to electric vehicles (EVs).

Installing any type of charging station comes with structural engineering challenges. Integrating electric vehicle supply equipment (EVSE) within existing facilities can be particularly complex — especially when factoring in the additional weight of the EVs themselves.

An EVSE retrofit will often require major facility modifications. In these circumstances, structural engineers are well positioned to ensure EVs and EVSE are integrated holistically within the facility’s design.

If engaged early in the project design process, the structural team’s design approach is more likely to limit the impact of project construction on facility operations and contain overall implementation costs.

Designing Electric Vehicle Supply Equipment’s Support Structures

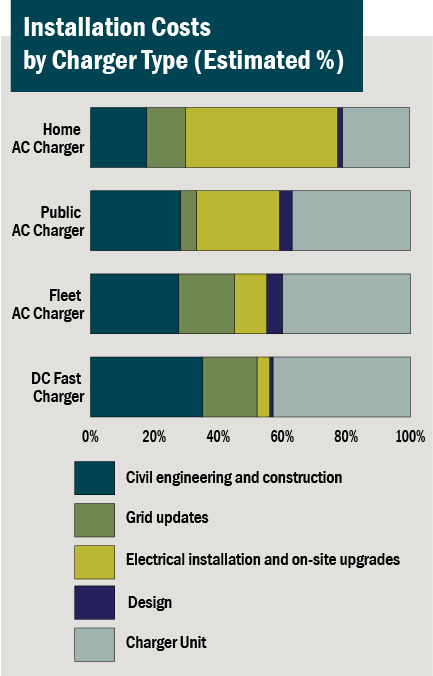

An EVSE project’s structural components depend on the type of charging installation, quantity of chargers, and project’s overall power capacity.

Structural components of workplace, residential, and public charging stations may feature:

- Pedestals – platforms carrying the load from supported chargers, typically made with concrete.

- Bollards – protective posts that serves as barriers to prevent vehicles from hitting and damaging the chargers, typically made of metal.

- Solar photovoltaic (PV) arrays – solar canopies offset increases in power demand and provide drivers with protection from inclement weather.

Fleet charging often involves more structural components. Potential EVSE designs include:

- Attaching EVSE to the facility’s roof or through canopy configurations, descending charging dispensers or pantographs above the EVs. Equipment could include switchgear, transformers, on-site power, and energy storage systems.

- Installing cable management systems to avoid risks of equipment damage or tripping hazards. Options include trench-based cable reels, overhead conductors, or mounted reels with auto-retracting cable reels.

- Implementing life safety upgrades to protect facilities in the event of vehicle or battery cell fires. Measures include fireproofing existing walls or constructing designated quarantine areas.

Source: PwC

Accommodating Vehicles’ Ballooning Weights

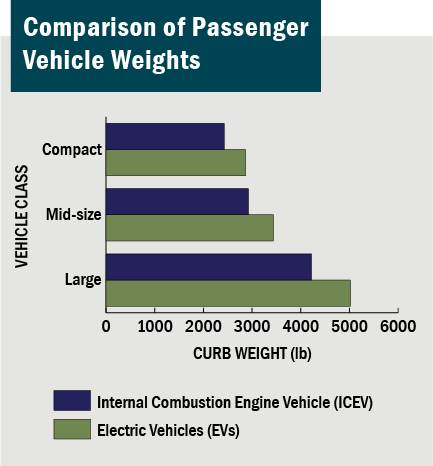

Structural considerations are not limited to how a facility accommodates the EVSE load. Parking and roadway designs must take into account how existing infrastructure can handle extra weight of EVs themselves.

After years of consumer demand for larger pickups and SUVs, EVs add hundreds to thousands of pounds of additional loads. Due to the significant battery size, an EV truck weighs approximately 8,400 pounds — compared to 6,500 pounds for a gas-powered Ford F-150. EV sedans are, on average, about 40 percent heavier than a standard internal combustion engine vehicle.

The extra weight comes after years of building codes reducing strength requirements. Over the past two decades, the American Society of Civil Engineers (ASCE) and American Concrete Institute (ACI) adjusted the minimum distributed load standard for parking garages, collectively reducing load requirements by 25 percent compared to pre-2002 levels.

That said, building codes generally require structural designs that ensure a facility withstands whatever loads the structure will handle over its lifetime (50 years, on average).

Garage structures will, in many instances, need to exceed minimum code requirements to accommodate vehicles’ growing weight. Without additional strengthening measures, parking structures will be at risk of greater maintenance, repair, and upgrade costs.

Source: Journal of Hazardous Materials

Strengthening New Jersey Transit’s Battery Electric Bus Depots

New Jersey Transit (NJT) is transitioning the agency’s bus fleet to zero-emission vehicles. In preparation, Burns is conducting State of Good Repair surveys across 17 NJT garages to identify infrastructure upgrades that will be necessary prior to EVSE installations, including structural modifications.

At the century-old Hilton Bus Garage, Burns is piloting an inverted pantograph system. Fast-charging plates will be mounted at set locations along a horizontal mesh steel curtain, descending onto charge rails attached atop the dozen battery-electric buses planned for the facility. The pantograph system is designed to be adjustable if bus storage logistics change in the future.

A structural analysis revealed the garage’s masonry bearing walls and steel trusses support bar joists that are not suitable for the new EVSE infrastructure. The facility is in need of extensive renovations. New structural steel framing will be integrated into the existing building to accommodate pantograph equipment and associated electrical upgrades. Additional modifications include new foundations to support the steel frames. Existing walls and floor slabs will be repaired or replaced as needed.

Early Collaboration Essential for Custom EVSE Installations

When undertaking an EVSE retrofit, best practice is to start with an assessment of exiting structural conditions. The analysis evaluates capacity to support new EVSE equipment, while constructability surveys determine load capacities for the columns and roof. Assessments also review mechanical, electrical and plumbing (M/E/P) systems to determine equipment relocation needs. In some circumstances, roofs may need to be reconstructed.

Engaging a structural engineer early in the process can prove pivotal for numerous reasons:

- Ensure accurate EV and EVSE weights are factored into the facility’s design

- Determine whether additional strengthening measures should be included in the project scope

- Locate EVSE in configurations that minimize structural impacts, reducing potential construction costs and avoiding disruption to facility operations

- Evaluate whether M/E/P or fire protection modifications will interfere with existing or planned support structures

In time, structural design standards may provide clearer guidance for EVSE installations. But even then, retrofit projects will always require custom solutions. Every structure is unique and comes with its own set of design challenges.

Burns is a full-service engineering firm providing the full breadth of interconnected design solutions from M/E/P and structural to technology, life safety, and security engineering services. Working collaboratively, our zero-emission mobility practice’s custom solutions can overcome whatever structural infrastructure challenges stand in the way of our client’s EV transition goals.

Source: McKinsey & Company