Smart and Safe Runway Construction Practices for Active Airfields

Keeping the nation’s runways in good working condition is critical to air travel safety.

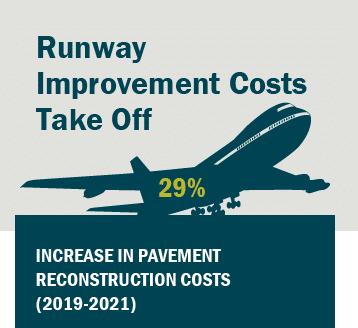

Yet rising labor and material costs risk delays for much-needed projects.

With some level of operational disruption unavoidable, airfield maintenance and construction projects can be daunting for airports of any size.

Innovative staging and phasing techniques can — if properly implemented — reduce project costs and help to limit impacts of construction on travel schedules, all while maintaining the safety of crew and passengers.

Phasing an Airfield Reconstruction Project

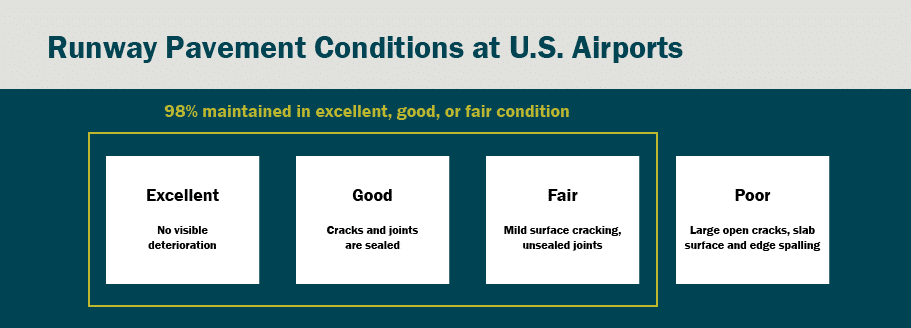

Airports must perform preventative airfield maintenance on a regular basis. Complete pavement rehabilitations occur, on average, every 15 years. Otherwise, reconstruction projects become exponentially more expensive over time. Occasionally, projects are initiated when airports face capacity constraints or changing aircraft standards.

The need to periodically protect, rehabilitate and reconstruct airfield pavement represents the greatest capital costs for U.S. airports.

Airfield rehabilitation generally involves one of three phasing approaches:

- Nightly closures over a period of successive nights.

Crew and equipment are escorted onto the airfield after runway shutdown and removed every morning in time for the runway to be inspected and cleared for operations.

- Full closure over a pre-planned, extended period.

Construction takes place for a longer, uninterrupted length of time — likely over a weekend or whenever air traffic is at its lowest level.

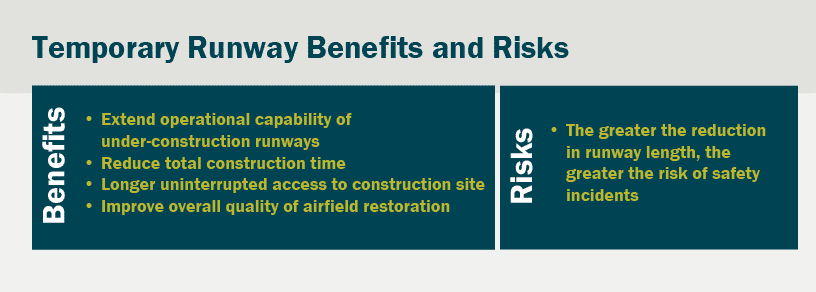

- Runway and taxiway reconfiguration, maintaining most operations.

Air traffic is temporarily shifted throughout the construction period, redirected to an alternate runway or taxiway. Reconstructed runways are shortened in phases — with takeoff and landing adjusted to a displaced threshold (DTHR) length.

Source: FAA National Plan of Integrated Airport Systems

Minimizing Operational Impacts

Source: FAA National Plan of Integrated Airport Systems

Regardless of the chosen solution, airfield construction teams must work around each airport’s operational and safety requirements. Closing or altering any portion of an airfield will have a direct impact on daily operating revenue, making advanced planning essential.

Extended closures or reconfigurations risk limiting the number of flights or reducing the total handled cargo. Such indirect costs must be taken into consideration when developing the required life cycle cost analysis for Airport Improvement Program funding.

Working with carriers and the Federal Aviation Authority (FAA), airports can adjust flight schedules around construction durations. But this can take months. After stakeholders are aligned, the airlines and air traffic controllers will need to be fully briefed to ensure pilots can prepare for shifts in airfield routes and accommodate revised takeoff or landing distances.

Proper safety precautions can ensure airfield modifications do not pose serious risks. During past safety incidents, causes included misunderstandings of the revised clearance distances, confusion due to poorly marked runways, or crews simply forgetting about the presence of construction activities.

Designing Temporary Runway Infrastructure

When creating a temporary runway, airfield engineers are provided limited federal guidance. Technique relies on careful interpretation of FAA regulations and field-tested experience in airfield construction best practices. Equipment designs, construction phasing and staging plans may involve months of careful preparation.

Airfield Ground Lighting (AGL)

Fewer fixtures may be necessary when designing a temporary runway. AGL systems must still be installed as permanent fixtures, however, fully in accordance with FAA lighting requirements.

Runway centerline and touchdown zone lights can be placed out of service. Only fixtures that establish minimum nighttime landing visibility are absolutely necessary:

- Edge lights

- Threshold lights

- Runway end lights

Guidance Signs

Poorly marked guidance signs can easily create confusion across the airfield. This is especially true on a dynamically changing airfield where temporary runways or taxiways run alongside the original pathways.

Simply installing a standard orange construction sign can maintain situational awareness. Such temporary signs do not need foundations.

Straightforward markings with instructions like “shortened” or “displaced” alert pilots of runway modifications. Risks can be further reduced by adding specific runway instructions such as the total takeoff run available (TORA).

Signage illumination lighting can utilize temporary wiring methods — either direct buried or surface mounted.

NAVAIDS and Visual Aids

Certain airfield navigational aids (NAVAIDS) are commissioned based on declared distances, making it very difficult to accommodate temporary shifts in air traffic.

Rather than risk confusion, cautious FAA requirements prefer these NAVAIDS be rendered out of service. During days of poor visibility, airports are required to redirect traffic to alternative runways.

Typically, decommissioned NAVAIDS include electronic instrument landing systems (ILS), visual approach lighting systems (ALS), and runway end identifier lights (REILs).

Precision approach path indicators (PAPI) lights, on the other hand, are relatively easy to relocate. Small and lightweight, PAPIs can be reconfigured with temporary foundations and rewiring of power supplies.

Pavement Markings

Arriving aircraft risk undershooting their landing or entering an incorrect runway if pavements are not clearly marked — or if obsolete paint markings remain visible.

Airfield crew must take extra caution to remove all existing threshold markings, including the approach chevrons and arrows.

Beyond pavement markings, runway closures can be easily identified with geotextile, heavy plate, or wood-and-fabric markings.

Customized Solution for Every Runway

Each airfield reconstruction project needs a customized strategy.

Projects at smaller airports may be able to accommodate a complete runway closure — provided sufficient labor and materials are available.

High-traffic airports likely cannot sustain the loss of revenue from a prolonged shutdown. Even if traffic is diverted to other runways, the impact on travel schedules can be unbearable.

Instead, temporary runways are becoming a popular solution. While not feasible in every situation, shifting runways can improve operational efficiency and enhance the quality of construction. When runways are closed for extended periods, contractors can pave longer lanes — spacing out the pavement joints — and improve long-term durability.

Airfield construction projects are the most critical to aviation safety. Designing a phasing strategy that meets the operational needs of airports and airlines, while upholding the safety of passengers and crews, remains among the most difficult and impactful challenges facing the aviation industry.