Signaling Design Best Practices Formalized in Rail Industry’s Updated Recommendations

The American Railway Engineering and Maintenance-of-Way Association (AREMA) recently issued new recommended design practices. The updated Communications and Signals Manual details how traction power systems can uphold rail condition detection, safeguarding passengers and crew.

Burns is a longstanding AREMA member, contributing expertise toward the review and revision of the association’s manuals of recommended practices. Along with peers from across the rail and transit industry, we are proud to participate in AREMA’s collaborative process of proactively updating the manuals’ widely followed recommendations.

The manual’s latest revisions are essential for formalizing rail safety best practices, influencing the design and construction of critical rail infrastructure systems.

Cross-Bonding Design Recommendations

To power electrified railways, train motors receive current from overhead catenary systems or a conductor “third rail.” The current eventually completes its path by traveling through the wheels and into the rails, making its way back to the traction power substation.

Signal control equipment relies on the same rails to determine train locations. If a train is on the tracks the signal current will be shunted by its wheels and provide an indication that the tracks are occupied.

If a rail segment breaks, however, the current will find an alternate path around the track circuit. The control system may show a false indication that the rail is unoccupied when — in fact — another train may be ahead. In other situations, improperly designing the traction power interconnection can mask broken rail incidents. When a broken rail is detected, train speeds are reduced — but only if the signal system can detect such an incident.

Due to these concerns, it is well established that the traction power supply and distribution system designs must be coordinated with the signal system designs. Careful attention needs to be given to the process involved when interconnecting impedance bonds, permitting traction return current to travel back to the substation.

AREMA’s Communications and Signals Manual, Section 8.6.14, offers clarity on how to design the electrical interconnection of rails between separate tracks, known as cross bonding, in a way that facilitates and balances the traction power return.

The updated manual’s cross-bonding design recommendations include instructions for how to avoid indiscriminate interconnection of the impedance bonds during installation and maintenance. Following this guidance is essential to avoid unsafe conditions and to limit instances of false signals.

Maintaining Safety Amid the Electrification Transition

Signal malfunction or design errors are increasingly rare. Still, the hazard analysis involved in any railroad system design aims to achieve as close to “zero risk” as possible.

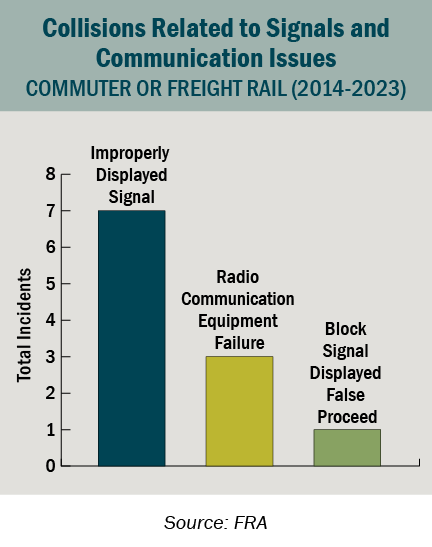

According to the Federal Railroad Administration, a total of 11 signals-related train collisions occurred along commuter or freight rail tracks between 2014-2023. Four were attributed to a block signal or interlock signal displaying false proceed indications. Federal data does not detail whether cross-bonding design was a factor in any of these incidents.

During the same ten-year period, broken or defective rail incidents were associated with roughly 3 percent of commuter or freight train derailments along the main track, according to FRA data. Again, it’s unknown how often cross-bonding design played a role.

AREMA members understand that extra precautions are necessary to avoid potential design errors and to mitigate any safety risks. The manual’s guidance is especially important as the trend toward electrification brings even greater scrutiny to traction power safety practices.

For example, last year Caltrain became one of the first U.S. agencies to electrify a diesel-operated rail corridor, converting the segment that connects San Francisco to San Jose. If more rail operators transition away from diesel-powered locomotives and toward all-electric transport, AREMA’s cross-bonding recommendations will prove increasingly important to ensure new electrified railways uphold the highest safety standards.

Caltrain electrified the formerly diesel-operated rail corridor between San Francisco and San Jose. Pi.1415926535, CC BY-SA 4.0, via Wikimedia Commons

Formalizing Best Practices, Sharing Knowledge

The AREMA manual revision’s recommendations do not contain novel design practices. These are cross-bonding best practices that electrical engineers and signal designers have deployed for decades. It was time for this knowledge to be properly documented.

Within the rail communications and signal engineering profession, too often design expertise is retained within a shrinking knowledge pool. Expertise is generally passed down from mentor to peer. Sometimes this involves little more than sharing a design sketch found within a decades-old spiral notebook.

AREMA’s manual revision protocols are essential during a time of generational change. As members of the baby boomer and millennial generations, respectively, we represent the passing of knowledge taking place across the engineering profession. Each retirement will bring a loss of institutional knowledge unless we formalize the notes sitting on our bookshelf and collaborate to memorialize engineering best practices.

AREMA’s manual revision protocols are essential during a time of generational change. As members of the baby boomer and millennial generations, respectively, we represent the passing of knowledge taking place across the engineering profession. Each retirement will bring a loss of institutional knowledge unless we formalize the notes sitting on our bookshelf and collaborate to memorialize engineering best practices.

The AREMA manuals are crucial resources for sharing the railroad industry’s safety-critical expertise. With this update to the Communications and Signals Manual, Section 8.6.14 demonstrates how the industry is collaborating to prepare the next generation of engineers and to ensure the continued safety of rail transportation.