Prefabricated Healthcare Construction Enters the Mainstream

Healthcare systems across the country are undertaking massive capital expansions and redevelopment projects. Undermining these construction goals, however, are the growing challenges of widespread labor shortages, supply chain disruptions, and complex design standards.

The latest estimates suggest demand for construction labor this year will outpace supply by more half a million workers. Workforce shortages will have major impacts on healthcare systems’ ability to fulfill capital objectives on schedule and within budget.

Building the country’s hospitals, inpatient treatment facilities, and nursing homes will require new levels of creativity. In response, owners, consulting engineers, and construction teams are turning to the increasingly prevalent solution of prefabrication.

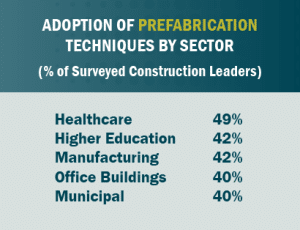

Healthcare Leads the Way

Prefabrication — also known as modular or offsite construction — leverages advanced manufacturing processes and design innovations to create a wide range of high-quality facility components. Assembled in an offsite location through a tightly controlled assembly process, prefabrication manufacturers offer components in standardized, compact units.

Once on site, prefabricated units can be installed through a more streamlined and uniform construction process. Oftentimes, prefabrication offers the benefits of accelerated delivery, lower cost of construction, greater quality control, and smaller environmental footprints.

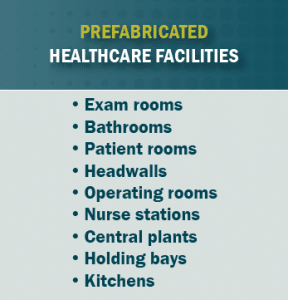

Prefabrication was once limited to easily replicable components, such as exterior structures or bathroom pods. Today, many options exist for prefabrication in a hospital environment. The largest and most-expensive units are generally best suited for prefabrication.

Within a prefabricated component, each pod is manufactured to include all the necessary infrastructure. This includes plumbing, ductwork, medical gas lines, electrical conduits, communications, and insulation.

Within a prefabricated component, each pod is manufactured to include all the necessary infrastructure. This includes plumbing, ductwork, medical gas lines, electrical conduits, communications, and insulation.

Even district energy systems can be built using modular, customizable units. Prefabricated central utility plants may contain chillers, pumps, boilers, and heat exchangers. Each unit can be fabricated to be compatible with chiller plants, boiler plants, and penthouses.

Prefabrication opportunities also exist belowground. Possibilities include piping and underground conduit, as well as in-ceiling chases and conduit racking. All of these can be preconstructed at an offsite facility and transported to the job site for installation.

Prefabrication Considerations

Prefabrication practices can produce significant benefits — but also come with potential challenges.

Prefabrication Benefits

- Enhanced Quality

Modular components are manufactured with skilled labor and undergo multiple quality checks. Designs can be perfected using building information management (BIM), computer aided design (CAD), and computer aided manufacturing (CAM) tools. Production within enclosed, clean facilities — rather than on the job site — reduces potential exposure to weather and other risks of damage. Testing and measurement processes take place before the products are brought onto the site, ensuring units work the first time they are put in service.

- Accelerated Project Schedules

Manufacturing units offsite can potentially shorten project schedules by 30-50 percent, according to the Modular Building Institute. Assembling the units can take place much earlier in the project development process, with multiple building trades potentially working concurrently. If the schedule demands an expedited timeline, factories may be able to stage their labor force to operate multiple shifts, keeping production going 24 hours a day. Working offsite also offers the benefit of fewer distractions, less time spent climbing into lifts or ladders, and fewer hours spent looking for misplaced equipment.

- Fewer Safety Risks

While manufacturing sites bring their own risks, in general, controlled off-site environments present fewer potential hazards. The safety records of most prefabrication factories are far superior to large construction job sites, and environmental risks have no bearing on worker safety. In tropical climates like in my state of Florida, weather has a major impact on construction conditions. Building with a prefabricated unit and it’s raining outside today? No problem!

Source: Buildings Journal

- Smaller Environmental Footprint

Offsite fabrication creates a more sustainable approach to construction. Waste is greatly reduced by cutting materials to the exact required lengths, nearly eliminating scrap leftovers. Plus, transportation of the prefabricated components can be achieved more efficiently, reducing the project’s overall energy intensity, while avoiding air pollution during delivery and installation.

Prefabrication Challenges

- Assembly Standards

When developing modular components, architects and engineers need to ensure the materials not only fit within the overall design framework. Design standards must also be designed for easy fabrication, consistent assembly, and minimal adjustments.

- Size Restrictions

Prefabricated components are hoisted onto trucks for delivery to the job site. The delivery strategy must consider whether each load can pass under the lowest bridge and along the narrowest road on the travel route. Depending on the distance from the factory, that can be a lot of bridges!

- Accurate Cost Estimates

Compared to traditional construction methods, the cost to produce and install prefabricated components is generally more predictable — but not necessarily less expensive. Costs depend on the application and design. Greater complexity may require more expensive materials or longer production time. Any incidents during delivery will have a major impact on the overall cost. Even minor damages can require costly repairs.

Photo courtesy of Epsilon Industries

Importance of Early Collaboration

Source: McGraw Hill Construction

Looking forward, a growing number of healthcare construction projects are anticipated to feature modular components. Prefabrication will become increasingly beneficial for healthcare systems across the country, especially as system manufacturers continue to become more versatile, healthcare facilities gain confidence in modular techniques, and labor shortages persist.

To fully take advantage of prefabrication, advanced planning and collaboration will take on greater importance. Architects, engineers, and contractors must work together from the beginning to identify which components would most likely benefit from the “rinse and repeat” approach of modular construction. Delayed discussions often lead to missed opportunities.

Initial planning efforts should ensure prefabricated components fit within the overall design and that the project won’t be hampered by unexpected logistical setbacks. The contractor must be completely on board — and early — to develop a construction phasing strategy that allows large components to be brought in and set. After all, once the building is completely sealed, it’ll be challenging to get that bathroom up through a freight elevator!

The repetitive, standardized nature of hospital bathrooms make them well suited for prefabrication. Each pod includes all necessary plumbing and fixtures as well as electrical, ventilation and communication systems.

Construction Reliability During Uncertain Times

At a time when healthcare capital programs face the uncertain futures of an insecure world, prefabrication offers much-needed predictability.

Prefabrication allows construction teams to create schedules that reduce delays, mitigates risk, and lowers overhead costs.

Perhaps most importantly, modular construction expedites the delivery of critical healthcare projects, expanding care sooner for the most vulnerable members of society.

Featured photo courtesy of Epsilon Industries