Powering Forward Automated People Movers

Automated People Movers (APMs) are a preferred transportation option for many airport campuses.

Quick, comfortable and convenient, electric-powered people movers are cost-effective solutions to relieve traffic congestion on airport roadways and to connect passenger terminals with ground transportation.

The popular mobility option continues to find new uses. Several projects are underway both at airports and within dense urban centers.

At the same time, APM resiliency is becoming increasingly complex. As airports and cities undertake widespread electrification initiatives, greater burden is placed on already strained grid resources.

To guarantee uninterrupted service in the event of equipment failure or a complete power outage, APM systems require special focus on traction power system design, ensuring the safety and welfare of the traveling public.

Brief History of Automated People Movers

In addition to improvements in microprocessors and software-based train controls, advanced traction power systems now make APMs among the safest, most-reliable forms of transportation.

APM technology has been evolving since the first development back in 1965. Partnering with Westinghouse Electric, the Pittsburgh-area’s Port Authority of Allegheny County showcased a computer-operated, rubber-tired electric tram on a two-mile elevated concrete guideway.

For five years, the project known as Skybus previewed a new vision for rapid transit. Larger plans for an 11-line Skybus “Westinghouse Transit Expressway” never materialized. But the APM concept caught on, capturing the attention of city planners and airport executives from across the country, as well as visionaries such as Walt Disney.

Starting with Tampa International Airport in 1971, APMs have since become a preferred system for transporting large volumes of airport passengers quickly between relatively close destinations. APMs are particularly useful for moving the public across restricted areas such as an airfield.

Automated People Movers Grow in Popularity

A half century after the first airport APM installation, people movers are experiencing a resurgence.

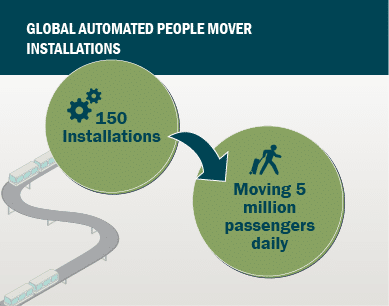

Today, more than 50 APMs operate at airports around the world. Projects recently completed or underway include systems at:

- Los Angeles International Airport (completing construction in 2023)

- O’Hare International Airport (re-opened in 2021)

- Orlando International Airport’s South Terminal Complex (opened in 2017)

Another 100 APM installations are located in urban centers such as downtown areas, hospital campuses, and entertainment districts. Projects currently under development include:

- Honolulu Authority for Rapid Transportation’s 20-mile Honolulu Rail Transit Project

- Inglewood Transit Connector between Los Angeles Metro’s new Cresnshaw/LAX extension and the growing stadium and arena complex

- A North Dallas linkage between the Dallas Midtown development and Dallas Area Rapid Transit’s new Silver Line

Source: Skytrax

Engineering People Movers

The engineering design for a fully automated, electric-powered transit system involves foresight into a wide range of operational and environmental circumstances.

Resilient designs require careful analysis of predictable APM system characteristics — such as system voltage and electrical load — as well as preparations for several potential events. Threats to system operations may include extreme weather, power disruptions, or security-related incidents.

Many APMs run on electric traction motors, self-propelled using rail-based power distribution subsystems. Traction power design must consider the system’s unique load profile, with detailed simulations that forecast the power capacity necessary to ensure continuous APM operations.

Power-demand simulations evaluate:

- Mode of operations. Options include continuous-loop or dispatchable systems.

- System route. Total system length, speed, pitch, and distance between substations.

- Passenger capacity. The capacity and number of operating vehicles and distance between vehicles.

- Auxiliary load. Power demand for stations and maintenance facilities.

- Future growth. Accommodations for adding vehicles or extending the system in the future.

- Contingency scenarios. Ensuring continued operations even during the loss of some critical power distribution infrastructure.

Power infrastructure must be sized and located to accommodate a myriad of contingency scenarios, such as a sudden loss of a rectifier or of an entire substation. In some systems, back-up systems are installed to prepare for even a complete utility outage.

Emerging Technologies Improve Resiliency

Electrified transit systems have been around for over 100 years. While rudimentary by today’s standards, those early systems were marvels of their time. As technology continues to advance, traction power systems are becoming more efficient, reliable, and compatible with electric utility providers.

For example, the development and widespread adoption of the 12-pulse rectifier, a critical power-conversion component for dc traction power systems, results in fewer harmonics and better overall power quality. This significantly reduces interference with sensitive electronic devices, minimizes heat, and allows transit systems to rely upon smaller and more economical electrical equipment.

For example, the development and widespread adoption of the 12-pulse rectifier, a critical power-conversion component for dc traction power systems, results in fewer harmonics and better overall power quality. This significantly reduces interference with sensitive electronic devices, minimizes heat, and allows transit systems to rely upon smaller and more economical electrical equipment.

While rectifier technology continues to improve, the industry is also evaluating controlled rectifiers. These devices can react to system loads and automatically adjust to best suit current operating conditions.

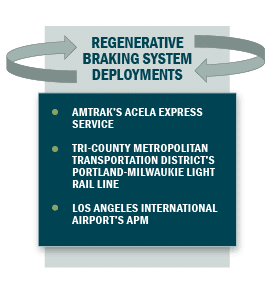

Another APM advancement is the integration of energy recapturing technology into traction power systems. Reversing the motor current, regenerative braking slows down vehicles while injecting energy back into the traction power network. This energy can be used by other vehicles on the system or diverted to an energy storage system (ESS).

Redirecting braking energy — otherwise wasted in the form of heat — offers a variety of benefits:

- Save, on average, 8-17 percent of system-wide energy.

- Bolster reliable service during outages, supplying power to help bring passengers to the nearest terminal.

- Dispatch stored energy to reduce system-wide peak demand and to lower greenhouse gas emissions.

- Transfer energy through the third rail, powering acceleration of nearby vehicles.

- Extend the lifespan of vehicles’ mechanical brakes.

Now applied widely in automobiles from passenger cars to Formula One racecars, various forms of dynamic braking and regenerative braking have been used by railroad and transit systems since the first electrified systems. As technology continues to evolve, system operators will be able to recapture and store greater amounts of this regenerative energy.

Resilient APM Operations

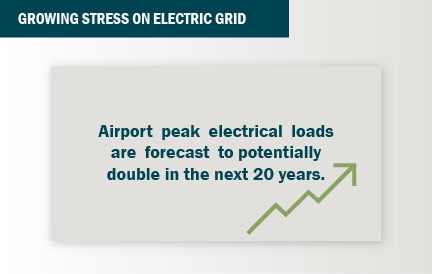

Greater electrification of airport campuses, cities and commercial centers make APM resiliency planning more important than ever before. Rising popularity of electric vehicles and electric heat pumps, for instance, will continue to drive up power demand.

APM resiliency plans are specified by each system operator. Some airports plan for partial outages, while others prepare for scenarios where redundant back-up generators are needed to power the entire system.

Climate resiliency is also becoming a greater concern. Coastal airports are increasingly including beyond-code elevation requirements in their system’s designs, ensuring guideways remain well above the floodplain.

APM systems are never quite the same. Each system operator develops their own design specifications, unique to their facilities and surrounding environment, and each APM manufacturer has their own proprietary technologies.

As a result, it is often difficult for airports, utilities, relevant authorities, and other stakeholders to oversee APM traction power system designs and to assess their impact on the regional grid. The variability in system designs makes collaboration among system engineers critical.

The variability in system designs makes collaboration among system engineers critical. The Institute for Electrical and The Institute for Electrical and Electronics Engineers (IEEE) continues to develop standards, guides and recommended practices for complex power networks. Serving on IEEE’s Vehicular Technology Society (VTS) Traction Power Systems Standards Committee (TPSSC), I am proud to help bring about greater clarity and best practices for traction power systems. This guidance will help to codify system-design requirements, streamline the design review process, and facilitate greater resiliency of APM systems.