Greater Boston’s Regional Rail System Installs State-of-the-Art Safety Improvements

A version of this article was previously published in Mass Transit.

Massachusetts Bay Transportation Authority recently achieved full Positive Train Control (PTC) functionality. The commuter rail safety system will result in lasting benefits for passengers, crew, and the traveling public.

MBTA’s new signaling infrastructure marks the culmination of years of safety upgrades implemented across Greater Boston’s commuter railways. PTC plays a crucial role in preventing train-to-train collisions, overspeed derailments, unauthorized work zone incursions, and movement through improperly aligned switches.

PTC benefits go beyond safety improvements. The technology will enhance operational resilience and reduce travel delays along MBTA’s 14 commuter rail lines, ultimately providing travelers with a more reliable commute.

Rail Safety History

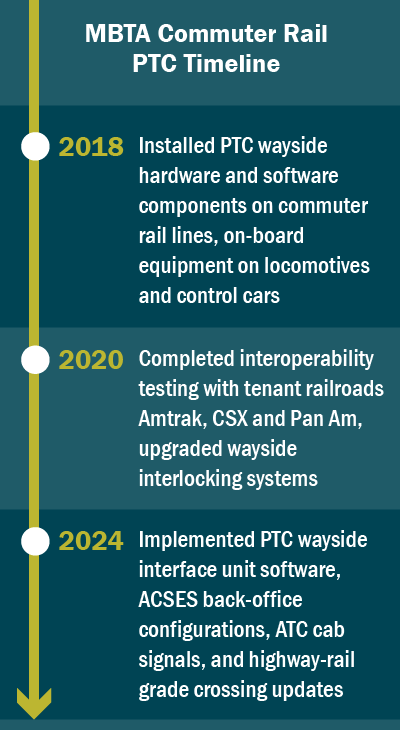

MBTA designated PTC as their top priority capital program. Over the past decade, MBTA followed a phased approach to install PTC systems throughout their 394-mile commuter rail system.

The federal Rail Safety Improvement Act mandated PTC in 2008 for the country’s Class I commuter rail lines and any railroads transporting hazardous materials. The Federal Railroad Administration (FRA) added further requirements for PTC system interoperability, ensuring continuation of PTC system operations and enforcements when trains travel either on a host or tenant railroad.

As of the end of 2020, PTC technology was operational on all FRA-mandated freight and passenger route miles. Read: An All-Aboard Success Story: Celebrating Positive Train Control.

That said, PTC installation is only the beginning. Full PTC functionality is an on-going process. It involves continual communications and signaling infrastructure upgrades, on-board systems updates, and testing to ensure interconnected technologies remain operational and interoperable with neighboring and tenant railroads.

MBTA’s phased approach started with the commuter rail lines running out of South Station. Because MBTA shares its south-side commuter railways with Amtrak’s Northeast Corridor, both operators’ PTC systems had to be fully interoperable. This involved installing Automatic Train Control (ATC) systems along with ACSES on each south-side line until, over time, the entire South side became equipped. Following a line-by-line testing and installation approach, today PTC systems are fully in place across MBTA commuter rail lines operating out of both North and South stations.

Positive Train Control System Components

PTC is a combination of technologies. The Advanced Civil Speed Enforcement System (ACSES) is overlaid onto ATC to create full PTC functionality.

ACSES uses wayside transponders, installed between the running rails, to provide data to an on-board ACSES system. When a train passes over the transponder set, the on-board system receives data updates such as speed restrictions for the territory ahead — either for upcoming bridges, sharp curves, or other route changes.

ACSES also receives temporary speed restrictions from MBTA’s dispatch. Audio and visual alarms alert the locomotive to reduce speeds or, if the train’s speed is not reduced in time, the ACSES system will automatically request braking. Doing so brings the train under speed limits when approaching a stop signal or interlocking.

ACSES also receives temporary speed restrictions from MBTA’s dispatch. Audio and visual alarms alert the locomotive to reduce speeds or, if the train’s speed is not reduced in time, the ACSES system will automatically request braking. Doing so brings the train under speed limits when approaching a stop signal or interlocking.

While traveling, the on-board ATC system receives requests for braking from the ACSES controls if the train needs to be slowed down or brought to a stop. When approaching another train, the on-board ATC system receives instructions on the speed limit that would allow for proper separation between vehicles. If the approaching train’s engineer fails to reduce speeds to below the allowable limit, the ATC system will automatically apply the brakes.

PTC’s Safety and Operational Benefits

PTC prevents derailments, collisions, and other safety risks along the tracks. In addition, ACSES and ATC cab signals are crucial to bolstering safety when trains pass between interlockings and through highway-rail grade crossings.

Beyond enhancing safety, additional benefits include:

- ATC enables closer train headway on select routes, potentially reducing travel times. MBTA’s redesigned automatic block layout integrates safety improvements without requiring operators reduce train speeds.

- Constant Warning Time (CWT) systems reduce wait times when vehicles are stopped at a highway-rail grade crossing. CWT tracks the approaching trains’ speed and distance, enabling better predictions for when to initiate crossing signals.

- ATC technology eliminates the need for legacy wayside signal systems, reducing MBTA costs to maintain State of Good Repair and, potentially, avoiding travel delays caused by wayside signal failures.

- The wayside signaling infrastructure’s electrical distribution systems are designed with enhanced resilience. The system feeds power from multiple sources, reducing the likelihood of a signaling power outage that could potentially disrupt rail operations.

The Work Goes On

MBTA is among the rail industry’s PTC leaders. Implementing the technology involved significant investment in resources and planning — all within an aggressive timeframe. PTC touches nearly every component of railway operations.

Yet the work goes on. MBTA recognizes PTC operations are dependent on reliable, efficient and high-capacity networks. In response, MBTA is undertaking a large-scale capital project to bury fiber-optic cables alongside miles and miles of commuter rail tracks. Considered the third phase of MBTA’s PTC program, the project will enhance resilience of local access networks, protecting critical communications from storms or accidents that could otherwise disrupt PTC performance.

The PTC transition is a demonstration of MBTA’s strong commitment to deliver a safe, reliable, convenient experience for travelers across Greater Boston. Burns is proud to have played a role leading PTC system design for MBTA’s historic rail safety program, integrating state-of-the-art technologies throughout MBTA’s legacy railroad infrastructure and locomotive fleet.