Fire Suppression Strategies for Maintaining Safety, Protecting Critical Equipment

This article was previously published on FacilitiesNet.

Fire protection strategies are becoming more complex. New approaches are needed as tried-and-true fire suppression agents are phased out and new hazards are introduced within existing facilities.

While most buildings rely upon sprinkler systems, certain high-risk facilities demand special hazard protections. Going beyond the basic sprinkler is generally required if water exposure poses a threat to facility equipment.

Suitable fire suppression systems are available for nearly every type of fire risk. Identifying the ideal protection system requires an understanding of facility-specific infrastructure, hazard risks, and occupancy characteristics.

Ensuring Life Safety, Protecting Vulnerable Equipment

Water-based wet, dry, pre-action and deluge protection systems serve as the best option in many cases to protect buildings and to preserve life. However, the area and assets being protected may experience damage and potential operational outages.

Due to these concerns, special hazard fire-protection systems are necessary to safeguard particularly sensitive or valuable assets. Advanced fire suppression systems are installed to minimize damage in hospitals, data centers, electrical substations, gas turbine generators, and alternative vehicle storage facilities, among other locations.

Hospitals, for example, ensure life safety with systems that can quickly contain flames before a fire reaches patient areas. Suppression systems are also used to protect high-value imaging equipment, information technology rooms, or flammable materials such as oxygen tanks, aesthesia gases, and cleaning products.

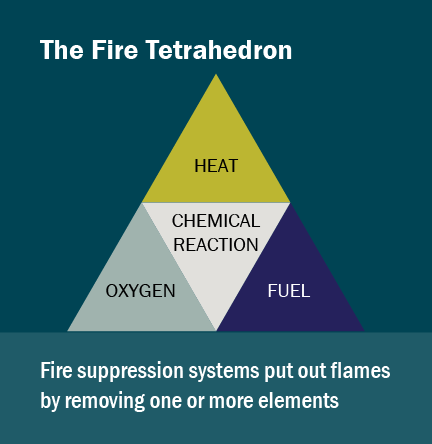

Fire suppression solutions range from simple gas extinguishers to complex installations combining various chemical and water-based systems. Options may involve aerosol units, foams, carbon dioxide, or water mist systems. “Clean agent” systems are popular for their ability to extinguish flames by absorbing oxygen from a contained area.

Environmental Reforms

Environmental regulations are forcing many facilities to transition to a new generation of fire suppression agents. This is especially true for facilities relying upon clean agent chemicals.

Clean agents flood an entire protected room or compartment with the gas agent — floor-to-ceiling and wall-to-wall — regardless of where within the space the fire is located. Clean agents do not dissipate until the fire event is controlled. Solutions are considered clean agents if they are electrically non-conducting and do not leave behind chemical residues upon evaporation.

Halon was long one of the most popular solutions until, in 1994, the United States banned production and import in alignment with international efforts to phase out ozone-depleting substances (ODS). Signing the international Montreal Protocol on Substances that Deplete the Ozone Layer committed the United States to phase out substances such as Halon.

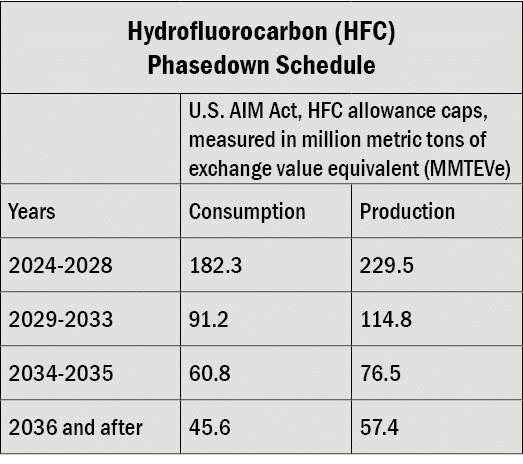

Since then, several non-toxic ODS alternatives have proven safe for the ozone layer and effective at controlling flames. Yet many have the unintended consequence of contributing significantly to global climate change. The clean agent FM-200, for example, is a popular alternative to Halon. FM-200 is a hydroflurocarbon gas (HFC) with a global warming potential (GWP) more than 3,200 times the potency of carbon dioxide.

The Montreal Protocol was amended in 2016 to discontinue certain carbon-intensive HFCs. In the United States, passage of the 2020 American Innovation and Manufacturing Act (AIM) authorized eventual phasing out of several HFC fire suppression agents. In response to these regulations, manufacturer 3M has instead promoted NOVEC 1230 as an environmentally sustainable replacement for FM-200. The clean agent is not known to deplete the ozone layer and it has a GWP less than carbon dioxide.

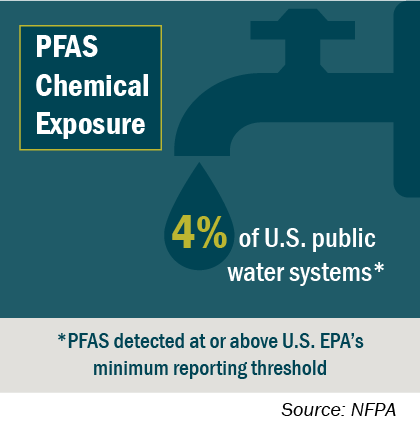

However, challenges continue. NOVEC 1230 is a polyfluroalky substance (PFAS). Production and disposal of these “forever chemicals” is associated with significant levels of water contamination, among other concerns. In 2022, 3M announced the company will exit PFAS manufacturing and discontinue use of PFAS across their product portfolio by the end of 2025. In doing so, yet another clean agent will become unavailable for purchase.

Fire Suppression Alternatives

Many contractors continue to source and install discontinued suppression systems. Facility owners who rely on a discontinued system may face supply shortages as well as the risk of higher replacement costs if the solution discharges. Proactively evaluating fire safety strategies can ensure that an alternative fire suppression agent is on hand whenever disaster strikes.

Common special hazard fire-protection systems include:

- Fike FK-5-1-12 – contains the same chemical properties as NOVEC 1230. Though it does not contribute to ozone depletion, and it maintains low global warming potential, discharging the PFAS may present environmental concerns.

- INERGEN-ANSUL (IG-541) – the clean agent combines nitrogen, argon, and carbon dioxide to lower oxygen content, disrupting a fire’s combustion process, while still leaving the possibility that occupants can breathe the air.

- Kidde Natura – the inert gas system uses 100-percent argon, 100-nitrogen, an argon/nitrogen blend, or argon/nitrogen/carbon dioxide blend. Occupants can breathe gas blends at extinguishing concentrations up to 52 percent.

- PROINERT IG-55 – the odorless, electrically non-conductive inert gas system lowers oxygen concentrations to levels that remain safe for humans to breathe.

- Viking OXEO – the inert gas system uses either non-toxic argon or nitrogen to absorb heat and cool the combustion zone. Compact storage tanks disperse gases homogenously at high pressure, removing oxygen even when fire sources are hidden.

- Stat-X – the condensed aerosol system does not require gas cylinders or piping. A mixture of chemical agents and inert gases, the system can be more expensive than other clean agents — but useful for protecting remote or rarely visited enclosures.

Carbon dioxide systems offer another alternative. But some local jurisdictions have begun phasing these out as well. The common gas is not considered by NFPA as a clean agent, though it effectively acts as one, removing oxygen while simultaneously working as a cooling agent. Carbon dioxide systems cannot be used within any occupied enclosures due to risks of exposure fatalities.

Site-Specific Fire Suppression Solutions

There is no one-size-fits-all approach when developing a fire-protection system. Configurations must be tailored to each building’s layout, occupancy trends, and code requirements — as well as the owner’s operational goals.

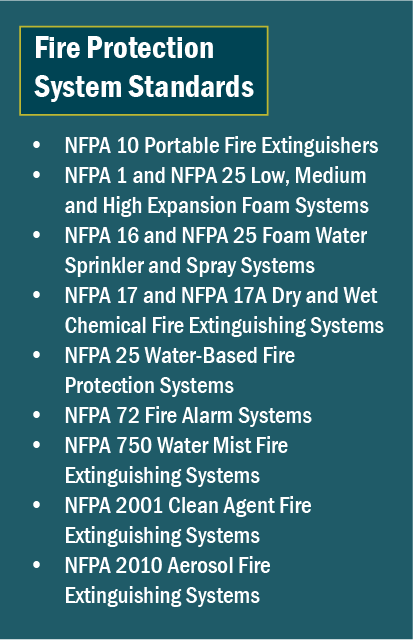

Fire protection strategies must conform with the local, state, and federal jurisdiction’s fire safety requirements, National Fire Protection Agency (NFPA) codes, and Occupational Safety and Health Administration (OSHA) standards, as well as insurance underwriter conditions. Other design factors include:

- Effectiveness

The most important consideration is whether the system provides necessary coverage, while safely addressing the facility’s relevant fire risks. Different suppression systems are needed for electrical fires or flammable and combustible liquid hazards.

- Structural Integrity

Clean agents require an airtight space to prevent gas solution dispersal. Oxygen levels will increase if a room has multiple openings for ductwork, doors, windows, or cabling — complicating efforts to control flames. In these instances, certain clean agents may not be appropriate.

- Space Availability

A clean agent’s tanks must be located in a secure area without risk of interference. Otherwise, any accidental damages could have disastrous consequences.

- Operational Controls

Suppression systems can be automated, interacting with early warning smoke, heat and flame detection devices, and coupled with local manual release actuation. Unlike with manual systems, automatic activation and discharge can be aborted if detectors are triggered by mistake.

Many options exist that can reliably and safely address most facilities’ fire hazards. Introducing new systems can, however, present design challenges and potentially add to the overall system cost.

Some owners choose instead to rely upon discontinued suppression agents. Given supply shortages and rising replacement costs, continuing with previous fire protection solutions may eventually backfire. Owners who do not modernize their facility’s fire suppression system do so at their own risk.