Electric Buses Renew Attention on Transit Maintenance Facilities

Public transit agencies are preparing for the biggest change to bus fleets in generations.

Attracted by zero tailpipe emissions, quieter streets and lower fueling costs, system operators are transitioning to battery electric buses (BEBs). The logistical challenges will be unprecedented.

Transit agencies will need to accommodate BEB infrastructure — all while ensuring they can continue to perform regular maintenance services for existing fleets of diesel, CNG or hybrid-electric vehicles.

Successfully electrifying our nation’s bus fleets requires a renewed appreciation for the often-overlooked bus maintenance depot.

The Role of Maintenance Depots

To keep electrified fleets charged and well-maintained, bus depots will carry an outsized operational role.

Bus depots include facilities and equipment for vehicle fueling, tire changes, washing, cleaning and fare collection, as well as routine inspections and mechanical repairs. Often, additional space is needed for spare parts storage, offices, and larger workshops.

“…expansion is especially challenging within urban areas where adding land or space comes at high cost.”

The BEB transition will entail a combination of re-engineering and logistical reinvention. Charging equipment and new electric vehicles will take up space, require new sources of power and resiliency, and otherwise involve a reconfiguring of maintenance processes.

More often than not, depots simply lack the room or structural capacity for new infrastructure. Budget shortfalls and under-maintained facilities add further complications.

Successful fleet electrification requires greater appreciation for bus maintenance depots, infrastructure and operations.

Aging and Overcapacity

Fortunately, transit agencies have mastered how to squeeze their bus fleets and complex maintenance operations into tightly configured, aging facilities.

The largest bus depot managed by the Southeastern Pennsylvania Transportation Agency (SEPTA), for example, has 270 parking spaces. But the facility is today used by a fleet of 320 buses.

In New York, the Metropolitan Transportation Authority (MTA) operates four Staten Island bus depots. Prior to recent construction of an 87,000-square-foot depot, parking for 800 MTA buses was impressively configured within facilities designed to accommodate only 500 vehicles.

Given the significant costs to procure BEBs and related charging equipment, transit agencies are unlikely to afford new facilities solely to accommodate their new electric fleets. Any expansion is especially challenging within urban areas where adding land or space comes at high cost.

Between actively addressing state-of-good-repair projects and managing competing funding issues, these priorities risk putting the brakes on BEB programs before they start. Roughly one-third of U.S. bus maintenance facilities are rated in inadequate state of repair by the U.S. Department of Transportation.

Solving Space Shortages

Few agencies are likely to downsize fleets. Instead, BEB pilot programs are expected to compensate for limited battery range by procuring an estimated 1.1-1.5 BEBs for every vehicle retired from current operation.

The alternative route — creative use of existing space — may involve stacking, hanging or mounting the new charging infrastructure.

In the transition to BEB, agencies will want to maximize the number of available spaces where charging equipment can be added.

Pilot program feasibility studies involve comprehensive reviews of available charging technologies.

The best place to start is an in-depth analysis of how the existing facility is utilized, assessing space constraints, direction of traffic, lay-over durations, maintenance routines, utility limitations and structural support systems, among other factors.

Plug-in Dispensers vs Pantograph Systems

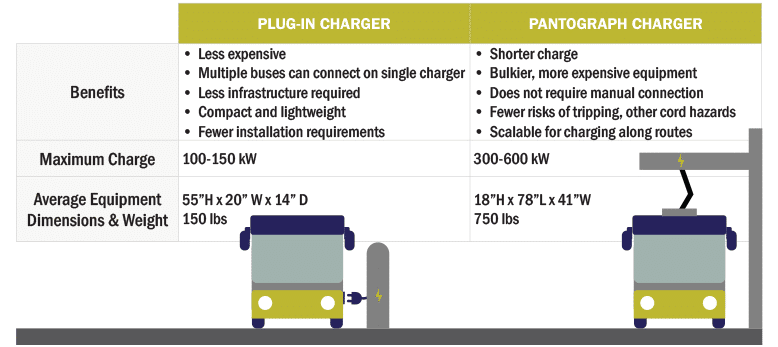

Charging system design begins with the decision of whether to install plug-in chargers or overhead pantographs.

A plug-in approach is generally less costly and, importantly, the power dispensers are compact and lightweight. Multiple power dispensers can connect to a single power station, known as sequential charging, to reduce overall charging infrastructure.

While plug-in chargers are less infrastructure intensive, the chargers take up space in an already congested area. A ground-mounted charger risks encroaching on vehicle movements and storage space. A roof-mounted solution prompts a structural analysis to evaluate the facility’s capacity to support new equipment.

Overhead pantographs charge BEBs at a fixed location mounted to the depot structure or within a free-standing pole. Charging plates or rails are located atop of each bus or mounted above at a fixed location.

In the United States, currently available technology limits installations to a single charging station for each pantograph. While this option avoids cluttering work areas with the plug-in system’s equipment and cords, modifications to bus operation procedures will need to be adjusted, such as by relocating buses after completing each charge.

Finding the Right Fit

Despite challenges, the transition to BEB operations can yield tremendous benefits for transit agencies and surrounding communities.

BEBs are likely to produce significant operational savings. If electricity costs remain generally stable, BEB fleets can recharge at potentially less than half the cost of refueling hybrid-electric buses.

Fewer moving parts could help reduce maintenance costs as well, while creating an enhanced work environment.

For the community, benefits include a reduction in air pollution and climate-warming greenhouse gas emissions, as well as quieter streets.

Put into context, the potential for advancements in public health, environmental sustainability and financial returns make the challenges of overhauling the nation’s bus depots seem not only worthwhile but truly necessary.

With the right creative solutions, bus maintenance facilities can rise to the occasion, becoming a crucial focal point in our nationwide shift toward electrified transportation.

This article originally appeared in METRO Magazine.