Combined Heat and Power Plants Are the Microgrid’s Beating Heart

This article is featured in the November/December edition of Facilities Manager

Combined Heat and Power (CHP) plants are unsung microgrid heroes.

With the ability to produce a continuous, controllable baseload source of electric and thermal energy, CHP remains a uniquely practical resource, especially for mission-critical facilities operating microgrids.

Yet, despite incredible benefits, CHP’s future potential may be limited as all-electric heating systems become more cost effective. In the age of rapid decarbonization, campus leaders are turning to district heating system technologies such as ground-sourced heat pumps or heat recovery systems that, unlike CHP, would operate without direct input of fossil fuels.

To fit within a zero-emission future, CHP systems need to adapt — or they risk becoming expensive, stranded assets.

Efficient, Reliable, Resilient Energy

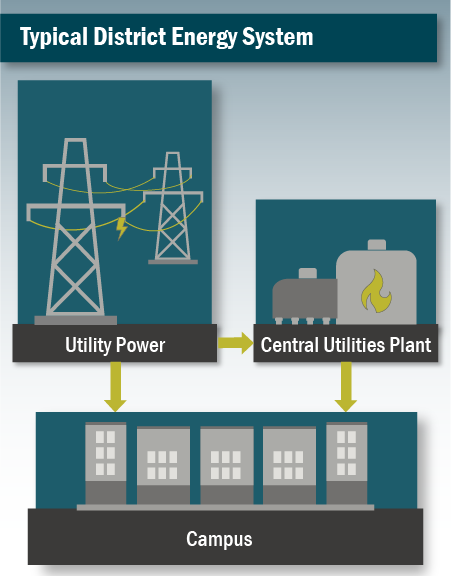

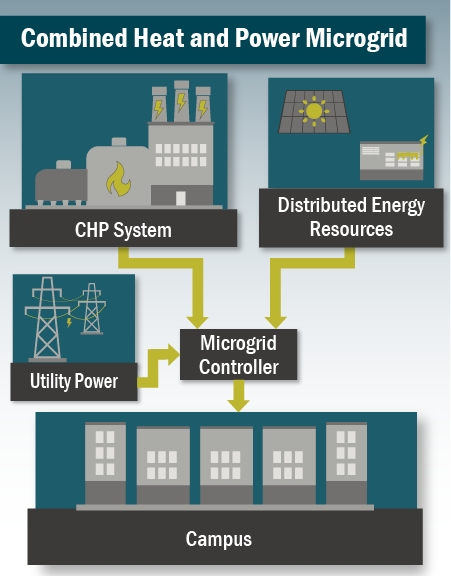

An advanced microgrid integrates dispatchable generation, typically natural-gas-fired generators, creating an independent network of energy assets. Flexible energy resources enable integration of intermittent, inverter-based energy sources such as solar photovoltaics (PV), coupled with battery energy storage solutions (BESS). Together, these distributed energy resources provide stable, resilient energy.

In real time, microgrids must match generation sources to the connected facilities’ load. A microgrid is significantly limited if generation is based solely on intermittent resources. Very large batteries would need to account for inter-day load swings — with even more capacity necessary to account for extended and unplanned outages. These back-up batteries would sit idle, charging in the event of an outage, and therefore provide little economic return.

Enter the anchor CHP system.

A CHP system provides a flexible, dispatchable electrical source that can respond in real time to these system dynamics. CHP offers the added benefit of being highly efficient. Also known as “cogeneration,” CHP systems generate electrical power while capturing thermal energy that would otherwise be wasted. The captured heat is applied to on-site loads, creating a highly efficient, reliable, and resilient district energy system.

Within a microgrid, CHP systems keep humming — even when solar PV production is low or batteries are depleted. Outside of planned maintenance activities, CHP plants provide uninterrupted yet efficient energy. CHP truly becomes the beating heart for resilient and efficient microgrids.

Carbon Conundrums

Motivated by carbon-reduction mandates or stakeholder-driven sustainability commitments, campus decision makers are increasingly choosing to shift to 100-percent renewables. In the not-distant-future, several district energy systems will be capable of running entirely on zero-emission thermal sources.

Phasing out natural gas-fired systems — CHP included — may seem like an intuitive decarbonization measure. However, electrification will result in dramatic increases to electrical demand, heightening the challenge for microgrid operations.

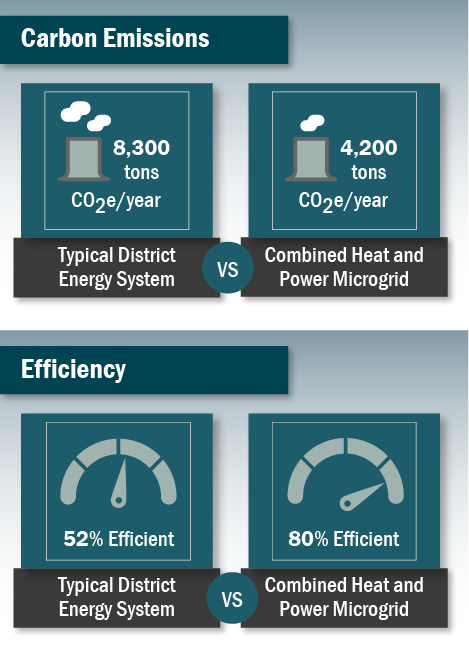

Excluding CHP from the energy mix also overlooks these systems’ pollution-reduction benefits. The grid remains roughly 60-percent reliant on fossil fuels, while three quarters of thermal energy comes from natural gas or heavy oil. As shown in the graphic below, a 1-Megawatt CHP plant operating a natural gas-fired CHP would emit nearly half the annual carbon emissions of traditional district energy applications — due largely to the plant’s capture and reuse of thermal energy.

Facility leaders must also consider how CHP systems offer other undeniable benefits, particularly at campus scale, including:

- CHP systems are scalable and can be customized to meet a microgrid’s specific design requirements.

- CHP plants are far more energy efficient than traditional energy options, achieving significant reduction in energy consumption as well as associated costs avoidance.

- Centralized CHP systems enable district energy campuses to provide both heating and cooling services in a central location. This reduces the need for on-site equipment in campus buildings, freeing up valuable real estate toward other core mission applications.

District energy system operating a fossil fuel-fired power plant and a natural gas-fired boiler (top) compared to a CHP microgrid operating a 1-MW reciprocating engine CHP system powered by natural gas (bottom).

Alternative Fueling Options

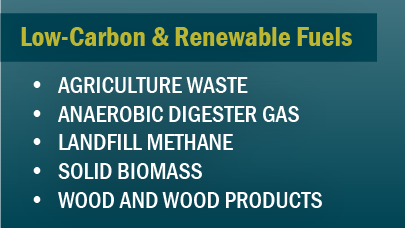

Campus leaders may not have to choose between installing CHP and decarbonizing. Modern advances in combustion and emissions control are opening up possibilities for CHP systems to reliably operate on alternative, low-carbon fuel sources.

Of the 215 currently operating CHP microgrids, only five rely entirely on renewable fuels, according to the U.S. Department of Energy. In practice, biofuel and renewable gas options remain expensive.

Production and distribution can be unpredictable. Many facilities lack capacity for on-site fuel storage, a key requirement for resilient operations in a low-carbon environment.

CHP installations can operate using fuel cells — a reliable, efficient, and scalable source of electricity. Fuel cells generate electricity by reacting fuel with oxygen through an electrochemical process to generate electricity (and waste heat). If the fuel cells’ energy source is hydrogen, produced using renewables, the CHP system can generate zero-emission electricity.

Conventionally, hydrogen is created from methane-based fuel sources, mostly natural gas or biogas. Hydrogen production from unabated natural gas results in an emissions intensity in the range of 10-14 tons of carbon dioxide equivalent per ton of hydrogen (CO2e/H2). Natural gas production’s upstream and midstream emissions are responsible for another 1 to 5 tons of CO2e/H2, according to the International Energy Association.

Looking ahead, hydrogen-powered fuel cells, turbines, and boilers may become cost effective as fuel costs fall and distribution networks expand. Federally funded “hydrogen hubs” promise to increase supplies of “green hydrogen” made with renewable electricity. Production currently remains limited with much development pending.

Don’t Sleep on the Benefits of a Thoughtful CHP Application

District energy facility leaders can either wait until cost-effective, low-carbon hydrogen resources become widely available — still several years out. Or they act now, installing a thoughtful CHP system with immediate economic and environmental benefits.

A properly configured and designed CHP solution can provide resilient microgrid power with dramatically reduced carbon intensity. Practical facility leaders are installing CHP systems with future proofing in mind, designing provisions that accommodate alternative fueling sources as they become viable.

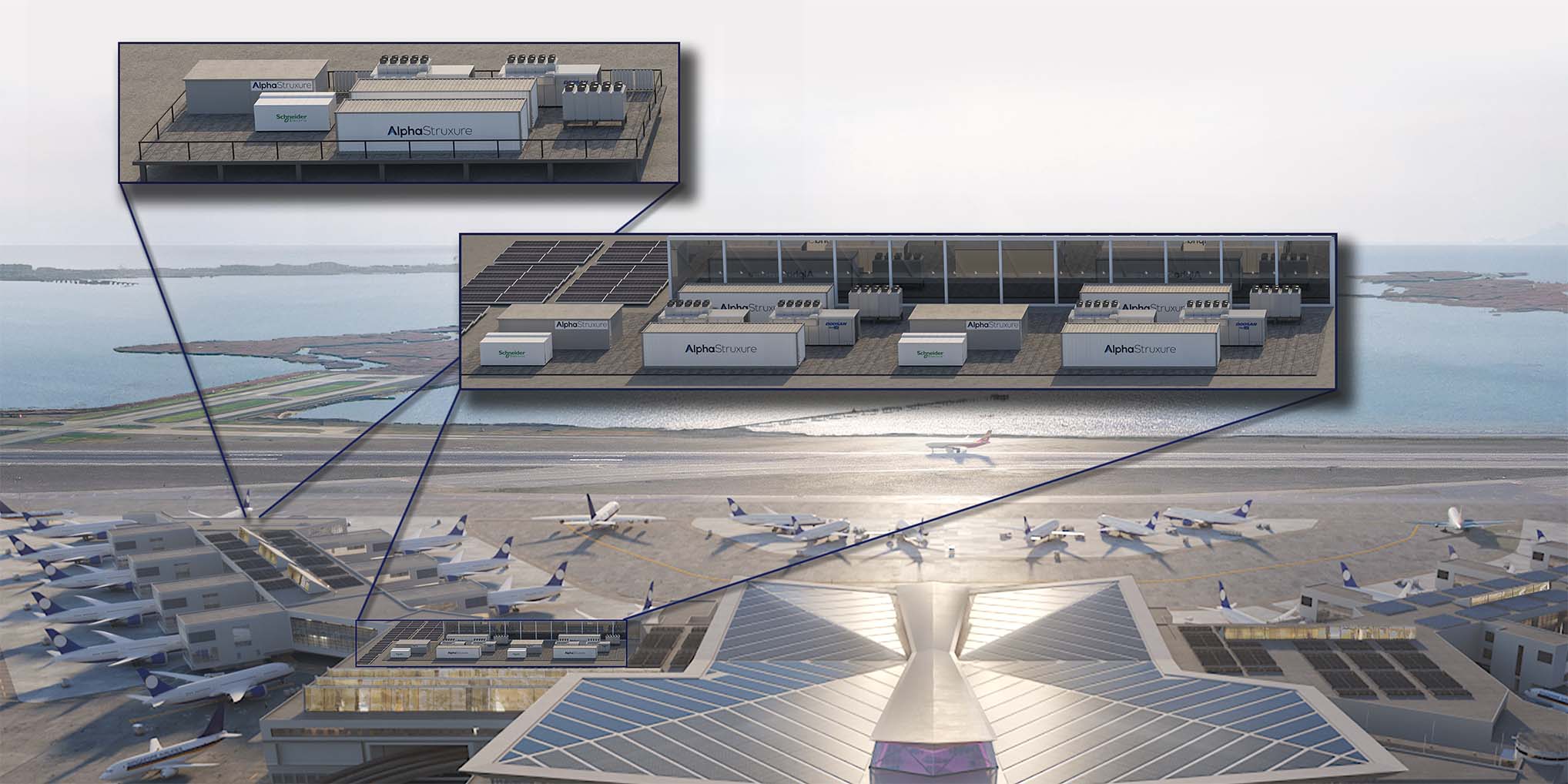

Burns has a long history of working with our clients to identify district energy systems best suited for their campus, maintaining operational resilience and reliability. In one recent example, Burns is supporting what will soon become one of the largest, most-innovative CHP microgrid installations. John F. Kennedy International Airport’s New Terminal One 11.3-MegaWatt (MW) microgrid will provide fully resilient, grid-independent power for the 2.4-million-square-foot, 23-gate facility. A 3-MW CHP system involves fuel cell technology with heat recovery for heating and cooling, exceeding minimum local air pollution control requirements.

Rendering of 11.3-MW microgrid planned for John F. Kennedy International Airport’s New Terminal One | Courtesy of AlphaStruxure

If a campus or district has a mutual goal of resilience with decarbonization, an optimized CHP solution presents facility leaders with a large step change and serious “bang for the buck.” CHP remains a powerful solution for getting every useful bit of energy from the system’s fuel sources.

Perhaps most importantly, CHP plants make microgrids work. All-electric heating systems increase reliance on limited power supplies, while CHP plants improve district energy systems’ resilience. Electric heating systems place added strain onto microgrids, while CHP plants enhance microgrid reliability.

CHP remains a solution few can afford to ignore.